Modern vehicles rely heavily on in-vehicle communication networks to connect ECUs, sensors, ADAS modules, infotainment systems, cameras, and powertrain components. For more than 30 years, the Controller Area Network (CAN) has been the backbone of automotive communication. However, with the rise of ADAS, autonomous driving, high-resolution cameras, radar, and infotainment, traditional CAN is no longer sufficient in many domains. This gap has led to the adoption of Automotive Ethernet, a high-bandwidth, low-latency networking technology tailored for advanced automotive applications. This detailed article explains Automotive Ethernet vs CAN, compares their architectures, data rates, cost, security, protocols, physical layers, and future roles in connected and autonomous vehicles.

Introduction to Automotive Communication Networks

Vehicles contain 70–150+ ECUs, including:

- Powertrain controllers

- Airbag ECU

- ADAS compute units

- Radar/LiDAR sensors

- Infotainment head units

- Body control modules

- Camera ECUs

- Battery management systems (BMS) in EVs

All these require reliable communication. Automotive networks must be:

- Real-time

- Deterministic

- Fault-tolerant

- EMI-resistant

- Low-latency

- Secure

- Cost-effective

For decades, CAN and LIN dominated low-speed and medium-speed automotive networks. However, with ADAS and data-intensive features, bandwidth demands have increased from 1 Mbps (CAN) to 1–10 Gbps (Automotive Ethernet).

What is CAN (Controller Area Network)?

CAN is a multi-master, message-based communication protocol developed by Bosch in 1986.

Key Characteristics of CAN:

- Data Rate is up to 1 Mbps (Classical CAN)

- Topology – Linear bus

- Medium is Twisted pair

- Determinism is High

- Prioritization – ID-based arbitration

- Error Handling is very strong

- Cost is very low

- Use Cases: Powertrain, chassis, body control modules

CAN is extremely reliable and efficient for short control signals, such as:

- Engine parameters

- Brake system

- Steering control

- Sensor status

- Battery voltage/current

- Airbag modules

Even today, 80%+ ECUs depend on CAN due to its robustness.

What is Automotive Ethernet?

Automotive Ethernet adapts standard Ethernet technology to meet automotive EMC, latency, and safety requirements.

Key Characteristics of Automotive Ethernet:

- Data Rate 100 Mbps, 1 Gbps, 2.5 Gbps, 5 Gbps, 10 Gbps

- Topology Star, bus, daisy-chain

- Medium Single twisted pair (100BASE-T1, 1000BASE-T1)

- Determinism Achieved via TSN (Time-Sensitive Networking)

- Cost Higher than CAN

- Use Cases: ADAS, camera streams, radar, infotainment, autonomous driving

It supports high-bandwidth data essential for:

- 360° Surround view

- High-resolution camera feeds

- Radar and LIDAR data

- ADAS fusion ECUs

- Autonomous vehicle compute platforms

- OTA updates

- High-speed infotainment systems

The main advantage is its massive bandwidth compared to CAN.

Why CAN is No Longer Enough?

Classical CAN supports 1 Mbps and CAN-FD up to 2–5 Mbps, which is insufficient for modern automotive demands:

- A single HD camera requires 100–150 Mbps

- LiDAR sensor generates 10–70 Mbps

- OTA updates require fast, secure transport

- ADAS fusion ECU demands high-speed communication

Thus, CAN is still used for control signals but is not suitable for data-heavy systems.

Automotive Ethernet vs CAN: Side-by-Side Comparison Table

| Parameter | Automotive | Ethernet CAN |

| Data Rate | 100 Mbps–10 Gbps | 1 Mbps (Classical) / Up to 5 Mbps (CAN FD) |

| Latency | Low with TSN | Low |

| Bandwidth | Very high | Low |

| Topology | Star, bus, daisy-chain | Bus |

| Cost | Higher | Very low |

| Error Handling | Moderate | Excellent |

| Determinism | Requires TSN | Built-in |

| EMI Immunity | Lower | Very high |

| Cable Type | Single twisted pair | Twisted pair |

| Message Type | Frame-based | Message-based |

| Use Cases | Cameras, radar, IVI, ADAS | Powertrain, BMS, airbags, BCM |

Communication Architecture Differences

6.1 CAN Architecture (Bus-Based)

Characteristics:

- Shared bus

- All nodes listen to all messages

- Arbitration determines the highest priority message

- Very rugged and simple design

6.2 Automotive Ethernet Architecture (Star-Based)

Characteristics:

- Switch-based routing

- Full-duplex communication

- Scalable for high-bandwidth applications

- Supports VLAN, QoS, TSN

Data Rate Comparison: CAN vs Automotive Ethernet

| Technology | Typical Bandwidth |

| CAN 2.0 | 1 Mbps |

| CAN FD | 2–5 Mbps |

| 100BASE-T1 | 100 Mbps |

| 1000BASE-T1 | 1 Gbps |

| 10GBASE-T1 | 10 Gbps |

Automotive Ethernet provides 100× to 10,000× more bandwidth than CAN.

Message Format Comparison

- CAN Frame

- ID field decides message priority

- Data length = 0 to 8 bytes (or 64 bytes in CAN FD)

- Strong error detection

- Broadcast communication

Ethernet Frame

- Source MAC

- Destination MAC

- Payload = up to 1500 bytes

- CRC

- Unicast/broadcast/multicast

Ethernet’s large payload is ideal for video streams and sensor fusion.

Latency & Real-Time Behavior

- CAN

- Highly deterministic

- Real-time due to priority-based arbitration

- Ideal for safety-critical systems

Automotive Ethernet

- Real-time behavior requires Time-Sensitive Networking (TSN) extensions

- Once TSN is added, latency equals industrial-grade real-time systems

Ethernet is suitable for ADAS and autonomous processing after TSN.

Reliability and Error Handling

CAN Reliability

- Cyclic Redundancy Check

- Acknowledgment

- Bit stuffing

- Retransmission

- Automatic error confinement

CAN is unmatched in terms of fault tolerance.

Ethernet Reliability

- CRC only

- No automatic retransmission at the physical layer

- Rely on higher-layer protocols

- CAN is more fault-tolerant in the physical layer.

Security Comparison

CAN Security Weaknesses

- No encryption

- No authentication

- Broadcast-based (easy to sniff)

CAN requires additional cybersecurity layers (IDPS, secure gateways).

Automotive Ethernet Security

- MACsec

- IPsec

- Secure VLAN

- Firewalls

- Authentication mechanisms

Ethernet is more advanced for cybersecurity.

Cost Comparison

| Area | Automotive Ethernet | CAN |

| Transceivers | High | Very cheap |

| Cables | Moderate | Cheap |

| Connectors | Expensive | Very cheap |

| Overall Network Cost | Higher | Lowest in automotive |

CAN remains the best option for cost-sensitive applications.

Power Consumption

- Ethernet consumes more power due to PHYs running at high speeds.

- CAN consumes very little power, ideal for low-power ECUs.

Example:

| Protocol | Typical Power Consumption |

| CAN | 50–100 mW |

| Ethernet (100 Mbps) | 300–500 mW |

| Ethernet (1 Gbps) | Up to 1W |

Use Cases: Where CAN Is Best

CAN is ideal for:

- Engine control

- Transmission

- ABS

- Airbags

- Steering modules

- HVAC

- Seat control

- Power windows

- Wipers

Advantages in these domains:

- High reliability

- Short messages

- Real-time control

- Low cost

Use Cases: Where Automotive Ethernet is

Automotive Ethernet is ideal for:

- Autonomous Driving ECUs

- ADAS fusion computers

- High-resolution cameras

- LiDAR sensors

- Radar modules

- Infotainment and connectivity

- V2X communication

- OTA updates

- Telematics

Ethernet is essential for high-speed data transfer applications.

Automotive Ethernet vs CAN FD

Many engineers ask:

“If CAN FD supports up to 5 Mbps, why do we need Ethernet?”

The answer:

- CAN FD still limited to 5 Mbps

- Payload limited to 64 bytes

- Not suitable for video streams or ADAS sensors

Ethernet fills this gap with 100 Mbps to 10 Gbps rates.

Future of Automotive Communication: Will Ethernet Replace CAN?

NO — Ethernet will not replace CAN entirely.

Both will coexist because:

- CAN is cost-effective and reliable

- Ethernet is a high-bandwidth

- Each serves different domains

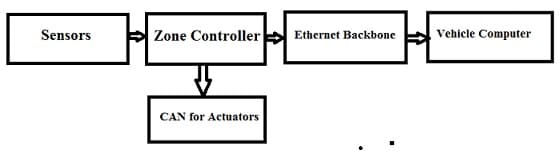

Typical Future Architecture (Zonal Architecture)

Automotive Ethernet vs CAN

Ethernet backbone + CAN for local controls = ideal architecture.

Conclusion: Automotive Ethernet vs CAN

— Which One Is Better?

There is no “one best protocol.” Each serves a specific purpose.

Choose CAN when you need:

- Low cost

- High reliability

- Short control messages

- Real-time determinism

- Rugged communication

Choose Automotive Ethernet when you need:

- High bandwidth

- Video and sensor data

- OTA updates

- Autonomous driving

- High-speed infotainment

- Secure communication

Modern vehicles use both technologies to deliver safety, performance, and user experience.

1. Is Automotive Ethernet faster than CAN?

Yes. Automotive Ethernet supports 100 Mbps to 10 Gbps, while CAN supports up to 1 Mbps (CAN 2.0) and 5 Mbps(CAN FD).

2. Can Automotive Ethernet replace CAN in vehicles?

Not completely. CAN is still required for low-level, real-time control. Ethernet is used for high-bandwidth systems like ADAS and infotainment.

3. What is the main limitation of CAN?

Its limited bandwidth (1–5 Mbps) and small payload size make it unsuitable for camera or sensor fusion data.

4. Why do autonomous vehicles use Automotive Ethernet?

Because it supports high-speed data required for camera, LiDAR, radar, and ADAS ECUs, which may generate hundreds of Mbps of data.

5. Is Automotive Ethernet more expensive than CAN?

Yes. Ethernet switches, connectors, and PHYs are more expensive. CAN remains the cheaper and simpler option.

6. Which protocol is better for safety-critical applications?

CAN is highly deterministic and fault-tolerant, making it better for real-time safety-critical control. Ethernet requires TSN to achieve similar determinism.